Industries

VERBINDUNGEN DIE SICH AUSZAHLEN Diesen Leitspruch haben wir unserem Firmenlogo hinzugefügt. Wir wollen damit die partnerschaftliche Verbindung zum Kunden all unserem Handeln voranstellen. Nicht nur das Produkt sondern auch der Service, allem voran aber die Zuverlässigkeit unserer Aussagen, schaffen zufriedene Kunden. Verbindungen müssen sich auszahlen, zu Ihrem und zu unserem Wohl. Menschen sind der Schlüssel zum Erfolg, bei immer ähnlicher werdenden Produkten. Ein gutes Betriebsklima fördert die Bereitschaft, unternehmerisch zu denken und zu handeln. Nur gut motivierte Mitarbeiter, die hinter dem Unternehmen stehen, leisten ihren Beitrag zur Zufriedenheit unserer Kunden.

Standing still is regression. We therefore live the continuous improvement process, which is also reflected in the optimization of our own products and processes. We are committed and gladly accept challenges. With our knowledge, we therefore contribute to our lead.

Sustainability. We also think about tomorrow and question our actions. This is how we distinguish ourselves for a quality-oriented future.

Quality. We not only work through our projects, but are passionate about what we do. This is what sets us apart and ensures that our customers are completely satisfied.

Responsibility. We have a high level of personal responsibility. Every project has a responsible person - from development to go-live.

Transparency. We document what we do at all times. This creates transparency in processes and cost analysis.

Partnership. We listen and are honest. Thus we find solutions together that lead to success.

Our philosophy. Commonality is our strength: colleagues of all ages combine our values of quality and responsibility with ever new ideas. Our employees stand for transparency and partnership in their various projects.

- zu Beginn der Flex-Fertigung

Die Unternehmen der Westa-Gruppe sind in unterschiedlichen Branchen weltweit tätig. Bereits in vierter Familiengeneration werden Produkte mit hohem technologischen Anspruch hergestellt und vermarktet. »Wir sorgen für gute Luft und sauberes Wasser«, so kann unser Angebot an Produkten und Dienstleistungen treffend beschrieben werden.

Marken sind Versprechen. Sie sichern mit Brief und Siegel Qualität und Tradition zu. Sie flüstern: "Ich bin aus gutem Hause. Bei mir kannst Du keinen Fehler machen." Sie versprechen außergewöhnliche Leistung und Perfektion in jedem Detail. Sie garantieren, dass niemand sonst dieses Produkt oder diese Dienstleistung besser machen oder erbringen kann. Das hat sie groß und mächtig gemacht, denn wer von uns hat schon Zeit, das riesige Angebot vor einer Kaufentscheidung zu durchforsten, um das Beste zu wählen?

Insofern ersparen sie uns unendlich Zeit und machen die Marktwirtschaft erst effizient. Mehr als jede Versicherung geben sie das lebenswichtige Gefühl von Sicherheit und Vertrauen. Sie versprechen, dass man angesagt ist und die richtige Entscheidung im Leben zu treffen weiß. Sie entlasten von dem Risiko, etwas Falsches zu wählen, lächerlich zu wirken oder zum Umtauschschalter gehen zu müssen. Die jeweilige Persönlichkeit mit allen Facetten von Verhalten, Lebensstil, Wertesystem und Ausstrahlung und mit all ihren Stärken und Schwächen prägt die Wahrnehmung der Marke im Markt; und die Marke mit allen Aspekten der Führung, Extension, Positionierung und Profilierung und mit all ihren Imagekomponenten prägt, wie der Namensträger von seiner Umgebung wahrgenommen wird. Das lädt eine ganze Menge Verantwortung auf die Schultern der Beteiligten.

In diesem Sinne nochmals: Nomen est Marke est omen! Mögen die großen Marken der Westa-Gruppe und die dahinter stehenden Wert- und Zielvorstellungen dauerhaft prägen. Wir wollen Vorbild sein in Demut, Disziplin und gesellschaftlicher Verantwortung.

- Made in OWL Ostwestfalen-Lippe

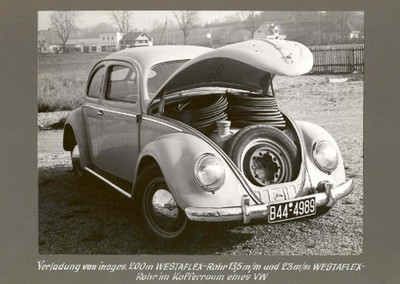

Für viele Auto-Legenden, wie Porsche 911 oder den VW Käfer liefert Westaflex seine legendären Flexrohre.

Fair behandelt, verhandeln und behandelt werden. Unser Motto für Verhandlungen und Besprechungen: denn nur wenn eine Win-Win-Situation entsteht, kann langfristiger Erfolg sichergestellt werden.

.

Company orientation

Fresh air together with peace and quiet leads to a good quality of life. Westaflex Industries in Gütersloh provides its innovative air conditioning and exhaust gas products to vehicle manufacturing, construction and trade customers on a global basis. These also include silent ACs for HVACR, be it in new buildings or those being renovated. Numerous product and process patents show the innovative spirit of the family-run business, headed by Dr. Peter Westerbarkey. Westaflex Industries has a proven track record, not just among the wholesale trade and within other industries. Even the Federal Environment Agency in Dessau uses Westaflex technology.

Over 85 years of Westaflex

That it runs and runs and runs... the probably most famous small car in the world also has to thank Westaflex for this. Over 85 years ago the brothers Ferdinand and Leonhard Westerbarkey used their patent for the production of flexible cooling tube for the VW Beetle. Even today Westaflex is still a family-run business. It is the specialist for air conducting, exhaust gas and building services both in vehicle manufacturing as well as in building construction. Westaflex’s services and products can be found on all continents. The quality and uniqueness of the product range is demonstrated by numerous patents. Westaflex R&D ensures that the customers always have state-of-the-art products at their disposal. In addition, the specialized in-house toolshop and machine building department ensures that even non-standard customer requirements can be fulfilled.

Research and development for tomorrow’s demands

Well-educated employees ensure new ideas and ongoing improvements in the workflow which leads to a reduced material usage at Westaflex. Thereby the manufacturing efficiency is increased. Modern machinery and coordinated, finely tuned processes with our suppliers and customers are also important prerequisites for continuing growth. Here we greatly profit from our long-lasting customer and client contacts. The term sustainability is paramount to us: Economic efficiency, the environment and social responsibility are the basis for the growth of this family business. At Westaflex, the employees are not just there for the company’s needs; our company is also there for the employees. Targeted further and continu- ing education increases the knowledge pool that the company can tap, this being the resource of the future. The in-house R&D department ensures that Westaflex will meet its customers’ future needs as well.

Creating space

In buildings and vehicles the space available for conduits of whatever type is usually quite limited. Westerflex tubes adapt to all situations. These tubes are bendable, flexible and compressible as well as available in any and every profile and width. The customized tubes provide planners and designers with space. The Westaflex range of tubes and connections can be easily worked with and handled just using standard tools.

Technology for the future

Westaflex does not just talk about the climate – with our products we provide a major contribution for a higher quality of life in a healthy environment in which one can easily breathe: air conducting technology that at the same time suppresses disturbing and irritating noises as well as lowering the energy consumption. Until 2020 in Germany alone approx. half of the newly constructed single-family detached houses and more than a third of the multi-family houses are low-energy or energy-efficient homes. This construction method places especially high demands on ventilation technology. These are requirements that Westaflex products more than fulfil. For example, the Westa Air Control Systems are highly valued nowadays by numerous customers as a guarantee for an ambient room climate.

Fresh air for a healthy life

Snatching some fresh air, going outdoors... The connection quality of life and fresh, clean air has become part of general linguistic usage. Outside we try to avoid places harbouring exhaust gases and fumes. Inside we feel comfortable if the air is fresh. A lack of ventilation does not only lead to a high concentration of carbon dioxide. It also allows for the spread of germs and fungi as the humidity is not regulated.

Feel the Silence

Acoustic units and low-noise air flow ducts are what Westaflex specializes in. They notably supplement the ventilation products that are provided by us. Not only the individual components, but the air control units as a whole are carefully checked as to their functions and it is ensured that they are compatible with each other. This is the basis for performance guarantees that we give to our customers.

Silent ventilation guarantees a good sleep

Disturbing distractions due to environmental noise in open-plan offices and night-time noise disturbances in inner cities due to technical systems and ventilation fans prevent peace and quiet. Concentrated work during the day and the peace and quiet necessary for a restful sleep at night can usually only be attained through acoustic units and mufflers. Often fresh air supply and acoustic muffling are closely interconnected. In the control rooms of rail vehicles and ships engine noise needs to be reduced and the transport of air within enclosed rooms has to be ensured. Here acoustic solutions by Westaflex can be implemented which are customised for each individual noisemaker. Mineral fibre-free mufflers that have a high fire protection classification as well as micro-perforated surfaces ensure peace and quiet.

Everyday quality of life

The Westa Air Control (WAC) for new buildings and for subsequent installation after renovation produces a healthy, pleasant climate in all rooms. The WAC retains and increases property value. Nowadays all buildings have to have an Energy Performance Certificate so that both buyers and tenants have all necessary information on energy usage at their disposal. And Westa Air Control helps to reduce this.

Controlled household ventilation

In kitchens, bathrooms and toilets humidity as well as odours develop. That is why Westa Air Control extracts the used air right here. Simultaneously, the same amount of fresh and cleaned air streams into all of the other rooms without there being a draft. During this process the WAC central control unit ensures that the warmth of the exhaust air is transferred into the fresh and newly supplied air. The tube and conduit system, the mufflers and the high-performance heat recovery to save energy are the core elements of the Westaflex controlled household ventilation. The building components system ensures that on-site nothing is missing and that no time is lost during assembly.

Central control unit

The core component of the system is the central control unit. A cross-current flow heat exchanger is operational within it that can regain the exhaust heat. The volume flow rate is uniformly regulated even if the filters contaminate and need to be exchanged.

Chimney technology

If a new heating system is needed, then homeowners should also think about the necessary adjustments of their chimney. Modern heating systems produce less hot exhaust gases. The suction in the old chimney is then insufficient and the exhaust gases lead to the development of an aggressive condensate on the inside of the chimney. Westaflex provides both fixed as well as flexible components made of high-grade stainless steel or plastic that can be easily assembled or inserted. Westaflex provides the trade industry with complete packages and guarantees their functioning if assembled correctly. Westaflex chimney technology fulfills all necessary standards and prerequisites. These products all have a CE label. They can be operated both with high or low pressure and are compatible with all fuel types.

Industrial solutions

Trade and industry are also being challenged when it comes to exhaust gas technology. Westaflex offers comprehensive consulting and planning services and puts into practice customer requirements as well as specifications. Hereby the aesthetic aspect of exhaust gas engineering is not ignored. The double-walled MSD system in stainless steel or in a copper optic can be set up for exterior and interior walls as well as a stand-alone solution.

Fresh air while on vacation

In campers and mobile homes there should be a cosy climate, even if it is hot, cold or wet outside. This means that the air must be able to circulate. The best solution always is if the traveller doesn’t notice this at all. Caravan manufacturers use Westaflex’s expertise when constructing and manufacturing flexible tube systems in order to attain the highest performance level regarding fresh air supply and heating whilst keeping the space taken up to a minimum.

Nearly invisible

In vehicles passengers do not really want to hear or feel the inflowing fresh air. Vehicles which have Westaflex products installed fulfill this high standard. Westaflex ventilation systems and tubes operate nearly invisibly in ACs, protecting sensitive components or are in use as mufflers. A cosy climate in vehicles heightens the concentration of the driver and lowers the risk of accident. With the experience of decades in this field, our company satisfies even the highest of customer needs and requirements.

No space is too small

In trains elongated heating and ventilation systems are in place. The challenge: The needed technology is not supposed to cramp the passengers. As the Westaflex tube systems save space and flexibly adjust to the wishes of the vehicle constructors, the manufacturers of trains and trams draw on the elastic products manufactured in Gütersloh. Westaflex products can also be found in cars, trucks, buses and ships.

Customized solutions

Fresh and pleasant air in the office improves the working climate. The federal government also knows this. It availed of Westaflex’s experience for the construction of the Federal Environment Agency building in Dessau. It took seven years for the planning and realization and in 2007 this highly modern building was completed. Nearly 600 Westaflex sound absorbing overcurrent components conduct the used air out of the offices into the hallway where they are extracted and the heat contained therein is recovered. This is more economic with regard to the investment and operational costs than the conventional exhaust systems. And safety also wins: In Dessau, Westaflex used for the first time components that automatically close in case of fire.

Connections that pay off

Westaflex is an inquisitive company, heading into the future with open eyes. In global competition ecology and sustainable economics are becoming more and more significant. On a daily basis new and exciting fields of activity are opening up for our company. Westaflex Industries is already present at a local level in numerous regions of the world and can be contacted at any time. Our employees listen, even if customers have nonstandard or challenging requests. For example, requiring customized products with regard to acoustics, ventilation and AC, exhaust technology or home ventilation systems and the respective specialized services connected with these.

WHATyouSEEisWHATyouGET

Dear business partner,

the companies of the Westaflex Industries are operating in different branches worldwide. Already in the fourth family generation our products are manufactured with high technological standards. „We make provisions for good ventilation and clean water“, this statement describes exactly our offer for products and services. On this webpage you will find information about our ventilation and chimney flue systems as well as the products for the controlled home ventilation and fluid filtration. Quality- and Environmental Management according to ISO, competent, technical support and a CNC aided machine park play an important role in the service to our customers. In the case that you do not already belong to the content customers of the Westaflex Industries we would like to awaken your interest for a business relationship with this brochure.

Yours Westerbarkey s

The modern factory and administration offices of westaflex industries lie approximately 1 km from the A2 motorway exit Guetersloh/Verl. Our company which was established in 1933 found here an ideal home. Today Westaflex Industries counts to the leaders in the range of technical products for ventilation, air-conditioning and exhaust removal systems. In the area of acustics we have provided solutions which meet the present day ecological demands necessary for a healthy environment. In July 1991 the ERO Stainless-steel Duct-technic Ltd. was established as a subsidiary company in Dambeck. Stainless-steel ventilation and exhaust gas systems are manufactured in this company. A new branch for the Westaflex Industries Holding is the aquisition of the Carbonit Filter technic. With a patented filter system not only the protection of health but also the longitivity of pipelines and equipment are substantially increased.

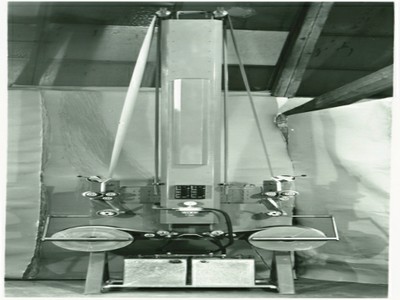

Westaflex is a large global HVAC (Heating, Ventilating, and Air Conditioning) owned by Westaflex Holding and based in Guetersloh, Germany. Founded in in 1933 by Lorenz and Ferdinand Westerbarkey, who developed a coil-based tube forming machine, the first stable and any-shape tube of its kind. During the 1960s, expanded into other international markets and is now present in 32 countries on five continents with a strong focus on Europe and North America. Westaflex products are used in a variety of applications including automotive production, train technology (ICE ventilation), for the air supply and ventilation of living spaces, exhaust technology and water treatment. Westaflex Industries has 2700 employees worldwide with around 250 at their headquarters in Gütersloh.

Westaflex Industries places a great deal of emphasis on the quality of its products and the role of employee participation, engagement and communication in achieving this quality. Ph.D. Peter Westerbarkey owns and successfully runs Westaflex and put a lot of effort into establishing a productive, innovative and open corporate culture. Westaflex's corporate motto is "connections which pay"; something which applies not only to their products but also to the value they place on the connections they have with their customers and with each other.

Connections that pay

This motto was introduced into our company logo for several years. That is, the partnership to our customer is of primary importance. Not only the product but especially the service and the reliability of our statements bring contented customers. Connections must pay, to your and our benefit. By the ever increasing number of similar products, people are the key to success. A good working climate promotes the willingness to think and act in the interest of the company. Only well motivated personell, who totally support the philosophy of the company, can contribute to the satisfaction of our customers. The convincing product advantages of the Wester-ducts and the comprehensive application possibilities have opened up a wide range of markets for these products. It is unimaginable to think that Wester-ducts may no longer be used for applications in the automobile, ventilation and air-conditioning, railway wagon construction, kitchen equipment and chimney producing industries.

Westaflex is one of the most innovative suppliers for technical solutions for the building industry regarding air-supplies. In 2001 the largest „passive house“ worldwide was built with Westaflex air-supply systems bedded in the concrete core.

ER stainless-steel ducting systems fullfil the high demands of a modern architectural visual application and the ventilation technological functions. Long-life, corrosion protection, hygiene and optic are characteristics of the ER stainless- steel ducting systems. Sound protection is an important requirement in ventilation and air-conditioning technology. Westaflex has many years of experience in the solving of acustical problems in the construction of flexible and rigid silencing elements named Westersilent. A new generation of silencers, type NONTOX, achieves a high attenuation performance without the use of absorbing insulating materials and opens up new fields of application. The acustical weather grids of the type XONEX combine the functions of fresh air intake and waste air grids with integrated silencers. The sound emission of the ventilating equipment in buildings is effectively reduced by the application of the acustical weather grids. Limited space conditions often hinder the installation of standard round ducts. An ideal solution is the use of the flat constructed Quadroflex ducts or silencers. With Westerquadro type Quadrofix, which has a smooth surfaced interior, the pressure losses are reduced.

Without doubt the controlled home ventilation plays a significant role in modern building projects as well as in the renovation of old buildings. Westaflex has developed for this segment of the market a complete product line (westa air control) from its own manufacture. Highly efficient central equipment with heat recovery bring fresh air into the home by extremely low energy costs. A metallic duct system of flat profile provides for a space saving distribution together with optimally designed air outlets and silencers, which bring the fresh air to the appropriate living area. Modern ventilation outlets transfer the prepared air via large outlet surfaces and low velocity into the rooms and achieve optimal room flow conditions. The comfort in the living/working area is increased considerably.

Chimney flue systems from Westaflex which have a quick, easy fitting plug and connecting technique, made of stainless-steel tubes for quick, efficient and economical re-furbishing of existent chimneys. These systems are not only suitable for new building projects but especially for the renovation of old buildings – dispenses with the necessity of brickwork alterations and is less time consuming. The substitution of a heating system with the appropriate chimney renovation can be completed without constructional difficulties. For the modern home, industrial and administration buildings the stainless-steel chimneys offer a wide range of architecturally appealing designs. The high quality, corrosion resistent materials provide a long life for the chimneys and the smooth inner surfaces optimal gas flow conditions. The cool, condensation burdened fumes of the calorific heating systems require pressure tight and corrosion proof chimneys. Through the installation of a new flexible chimney system, not only the requirements of the gas flue have been met, but also the flexibility of the system permits the re-furbishing of difficult existing chimney flues without the time consuming necessity of removing brickwork.

Our most important foodstuff is drinking water. Industrial processes and household installations may have an effect on the water quality. Carbonit Drinking Water Systems reduce a wide range of contaminants of health concern (i. e. chloride, specific bacteria, pesticides, heavy metals, and medical residues). The Carbonit Monoblock is a solid carbon block filter and made of activate carbon according to a secret process. It combines a filter fineness of up to 0,45 μm (mechanical filtration) with an extraordinary adsorption effect inside. The size and dimension of a Carbonit filter can be adapted customer specifically and may also include a housing.

An extensive warehouse for our standard products and the favourably situated position of our factory in Germany make it possible to guarantee a short delivery time. Our own fleet of vehicles and friendly, knowledgable drivers ensure careful transport of goods and last but not least a satisfied customer.

Background to Enterprise 2.0 Efforts

Web 2.0 and its interactive capabilities are growing in significance and are particularly relevant for medium-sized companies. Internet applications can produce perceptible competitive advantages when used as solutions for marketing, corporate communication or knowledge management. Westaflex GmbH, located in the Westphalian city of Gütersloh, shows particular commitment in this regard. “We provide good air and clean water. With use products made from aluminium, stainless steel and plastic to create living space” says CEO Westerbarkey, citing the company’s slogan.

Westerbarkey, too, stands confident: “We believe that the days of monologue on the Web have ultimately given way to dialogue, which, on the other hand, means that we have to react correspondingly.” For many industry managers, this may still be unimaginable. Online activities in which employees represent their own company on the Internet consume time, be it blogging, twittering or using social networks. One often-sounded argument is that there is no time for leisure during working hours. Westerbarkey, too, admits that this kind of online culture isn’t for everybody, but rather has to be a good match for the respective company. One stipulation is that there be an open corporate culture in which employees have plenty of room to make their own decisions. After all, the CEO doesn’t have to do it all himself. He says it is at its most authentic “when the team does it”.

Corporate culture is key

Westaflex’s support of manufacturing projects within cloud environment could be extremely successful. This combination of all communication tools around a project would allow people to keep a clear awareness of what is happening. Westaflex also believes that this openness needs to extend outside the firm walls to the company's customers and the wider world as a self-organising system that would give us enormous flexibility and helps perfectly meet the needs of SME.

Marktführende Unternehmen aus der Automobil- und Elektrobranche, sowie Beschlaghersteller der Tür-, Fenster- und Haushaltsindustrie vertrauen auf unsere hochpräzisen Produkte.

Die Westa-Holding GmbH & Co. KG überwacht weltweit die Liquidität aller Unternehmen der Westaflex Industries Group. Ihre Schwerpunkte decken die Bereiche Cash-Management, Beteiligungscontrolling, Informationstechnik, Personalmanagement und -entwicklung, sowie den gesamten Bereich Finanzen ab.

Made in Germany. Durch ISO-zertifizierte Zulieferer aus der Region und die Verwendung von hochwertigen Materialien wird ein Höchstmaß an Qualitätsstandards erreicht.

Westaflex is an independent, modern company with a long family tradition, noted for its down-to-earth stability, global orientation, emphasis on lasting values and innovative strengths. Our company history goes back over eighty years and has been marked by constant developments, continued investments and forward-looking decisions, which have in their turn propelled Westaflex’s growth to become a successful international corporate group.